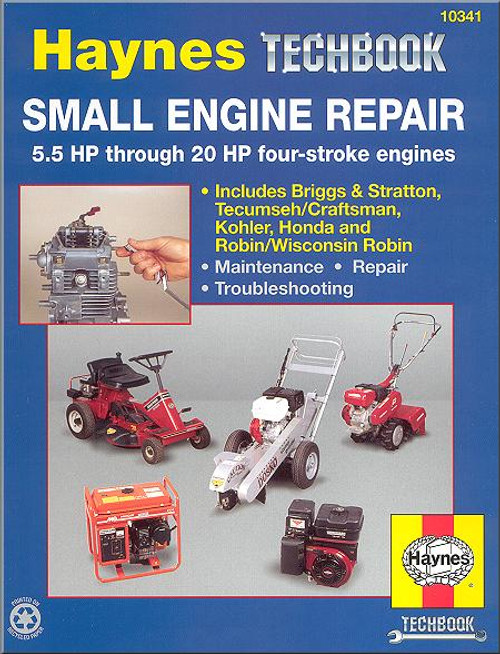

Repair, maintain and troubleshoot lawnmowers, snow blowers, leaf vacuums and more using the Small Engine Repair Manual by Haynes. The manual covers small engines made by Briggs and Stratton, Honda, Sears Craftsman and Tecumesh up to 5 HP. The manual includes sections on servicing engines, making repairs and troubleshooting. The manual is designed for DIY users and features easy-to-read instructions and helpful diagrams.

The Haynes manual is a truly comprehensive resource for small engine repair. The manual goes beyond repairs, maintenance and troubleshooting to include sections on general shop practices, safety and setting up your workspace. It includes helpful information on choosing tools and tips from professionals on what did and did not work for them. With the Haynes manual, you'll benefit from the combined knowledge of dozens of professionals that have been there before you.

This DIY repair and service manual by Haynes covers the following small engines:

- Briggs and Stratton side-valve four-stroke engines

- Honda four-stroke engines

- Sears Craftsman side-valve two- and four-stroke engines

- Tecumseh side-valve two- and four-stroke engines

Buy today so you can maintain your small engine tools today. The Motor Bookstore has been serving DIY and professional mechanics since 1997. We offer Free Shipping to US48 customers.

Book Excerpt

REPAIR PROCEDURES COMMON TO ALL ENGINESPISTON/CONNECTING ROD INSPECTION If the cylinder must be rebored, there's no reason to check the piston, since a new (larger) one will have to be installed anyway. Before the inspection can be carried out, the piston/connecting rod assembly must be cleaned with solvent and the original piston rings removed from the piston. NOTE: Always use new piston rings when the engine is reassembled - check with a dealer to ensure the correct ones are purchased and installed.

- Using a piston ring installation tool, if available, or your fingers, remove the rings from the piston (see illustration 5.24). Be careful not to nick or gouge the piston in the process.

- Scrape all traces of carbon off the top of the piston (see illustration 5.25). A hand-held wire brush or piece of fine emery cloth can be used once the majority of deposits have been scraped away. Do not, under any circumstances, use a wire brush mounted in an electric drill to remove deposits from the piston - the piston material is soft and will be eroded by the wire brush.

- Use a piece of broken piston ring to remove carbon deposits from the ring grooves (see illustration 5.26). Special tools are also available for the job. Be very careful to remove only the carbon deposits. Don't remove any metal and don't nick or scratch the sides of the ring grooves.

TECUMSEH/CRAFTSMAN ENGINES

VERTICAL-PULL STARTER - VERTICAL ENGAGEMENT

- Pull the rope out far enough to lock it in the V-shaped cutout in the bracket.

- If you have to remove the handle, pry out the staple with a small screwdriver.

- Place the starter bracket on top of a deep socket large enough to receive the head of the center pin, and then drive out the pin.

- Rotate the spring capsule strut until it's aligned with the legs of the brake spring. Insert a pin or nail no longer than 3/4-inch through the hole in the strut so it catches in the gear teeth (see illustration 7.17). This will keep the capsule in a wound position.

- Slip the sheave out of the bracket. Caution: Do not attempt to remove the spring capsule from the sheave assembly unless it's completely unwound.

- Squeeze and hold the spring capsule firmly against the gear sheave with your thumb at the outer edge of the capsule.

- Carefully remove the retainer pin from the strut and slowly relieve your grip on the assembly so the spring capsule rotates in a controlled manner to unwind completely.

Subject: Small Gasoline Engines: DIY Repair: Small Engine (up to and including 5 H.P. engines) repair manual. ISBN-10: 1850106665 | ISBN-13: 9781850106661 | Haynes 10340

- SETTING UP SHOP: Finding a place to work | Tools and equipment needed | Special factory tools

- GENERAL SHOP PRACTICES: Safety first! | How to use and buy tools | Precision measurements | Basic maintenance and repair techniques | How to remove broken bolts and repair stripped threads | Small engine lubricants and chemicals

- TROUBLESHOOTING: How an engine works | Introduction to troubleshooting | Troubleshooting a four-stroke engine | Troubleshooting a two-stroke engine

- TUNE-UP AND ROUTINE MAINTENANCE: Introduction | Tune-up and maintenance checklist

- REPAIR PROCEDURES COMMON TO ALL ENGINES: Engine removal and installation | Muffler removal and installation | Shroud/recoil starter removal and installation | Oil seal replacement | Carburetor removal | Carburetor overhaul | Engine block cleaning | Engine block inspection | Cylinder honing | Crankshaft and bearing inspection | Camshaft and bearing inspection | Piston/connecting rod inspection | Piston ring installation | Valve/tappet inspection and servicing

- BRIGGS and STRATTON ENGINES: Engine ID numbers/models covered | Recoil starter service | Carburetor disassembly and reassembly | Carburetor adjustment | Engine disassembly | Inspection of components | Engine reassembly

- TECUMSEH/CRAFTSMAN ENGINES: Engine ID numbers/models covered | Recoil starter service | Carburetor disassembly and reassembly | Carburetor adjustment | Four-stroke engine disassembly and reaseembly | Two-stroke engine disassembly and reassembly | Inspection of components

- HONDA ENGINES: Engine ID numbers/models covered | Recoil starter rope replacement | Recoil starter spring replacement | Carburetor disassembly and reassembly | Carburetor adjustment | Engine disassembly | Inspection of components | Engine reassembly